In this post I’ll talk a bit about the work of a local crew on the Bayside and Tidewater. These guys deserve a lot of credit since they get very few breaks during a session. Wayfreight, Transfer, Interchange, and Passenger crews all get opportunities to look around and/or chat while they are waiting for clearance to proceed – usually as a result of a local crew finishing up some work feeding cars to a waiting wayfreight. The local guys don’t have these opportunities.

The local crew’s shift starts when the session starts. They have to pull the outbound cars first so they will be ready for the wayfreights when they arrive. The priority is to pull the cars heading in the direction of the first wayfreight to roar into town. For the Stevenville job this would be the West Bound Wayfreight. So, the Stevenville crew needs to pull all the west bound cars fairly quickly. Westbound from Stevenville is pretty much everything on the layout – Derwin’s Drop, Kenville, Chappellton, and Tidewater Yard. So there are usually a lot of cars to pull.

If they study their orders they will see that some industries have cars heading in both directions during the session. The crew can save some time by pulling all outbound cars at once, but they need to keep them sorted for outbound direction and destination.

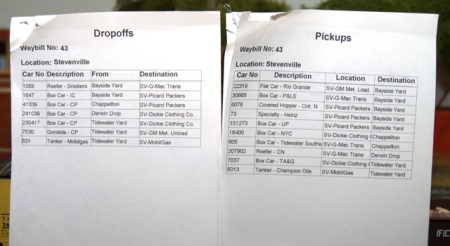

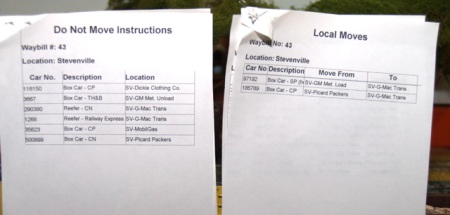

All crews are given a switchlist, or a printed list of cars that they are responsible for during the session. Local Crews get a list of Pulls, Deliveries (drop offs), Local Moves, and Do Not Moves. These are printed by a computer program I developed many years ago. Other crews get a variation of these orders depending on the tasks they have to perform.

The lists above show the major work that needed to be done is Stevenville during the last operating session. Each set of orders is numbered so that if there are more than one set printed at a time they can be kept separate from one another. I’ve used the term “Waybill #” but it probably would work better with the term “Session #”.

As you can see on the pickups list, it tells the local crew which cars to pick up, where they are located, and the next destination (town) that they are going to. Cars on the list are sorted by next destination so crews can sort outbound cars easily. It makes it a bit of a challenge when pulling cars because they are not sorted by present location. AS a result, crews have to study the orders carefully to determine the most efficient way to go about their work.

Wayfreights drop off cars in two batches. In Stevenville, the West Bound Wayfreight drops off cars first, about 20 – 30 minutes after the session starts. It only drops off cars from Bayside Yard, so there aren’t many. There were only two dropped off from Bayside Yard during this session.

About 30 – 40 minutes later the East Bound Wayfreight pulls into town with the remainder of the deliveries. The East Bound Wayfreight dropped off 5 cars during the session.

Occasionally there are cars that must be moved from one industry to another in the same switching area. The Local Moves list handles that. There are rarely more than 2 or 3 of these moves per session.

The Do not Moves list just shows what should be left at each industry after all the pulls are made and before the deliveries are done. Once in a while operators pull a cut of cars from an industry and get them mixed up with a cut from another industry. The Do Not Move list helps figure out where mis-pulled cars should be.

Because the program generates car movements randomly, each session is slightly different. I believe that during the next session Stevenville will send out about 12 cars and receive almost 15.

Later!

Scott