The goals of the UMG (Un-Named Modular Group) are to promote the hobby of model railroading and to expose people to the operations side of the hobby. Some would argue the primary goal is to have a good time with a bunch of great guys, but that’s actually just a bonus.

One of the things that we encourage our “members” to do at public shows is to talk to visitors and explain what we do, why we do it, and how we do it, even at the expense of blocking the main line. During shows we have to have a “sweeper operator” go around the layout and move trains abandoned by operators engaged in deep conversation with a visitor.

One of the most common topics we get asked about is DCC. The amount of misinformation that is available on the web, and supposed “common knowledge” of non-DCC modelers, is astounding.

I’ve discovered a few sites lately with a lot of great information about DCC that I’d like to share. They shed some light on the myths and misinformation.

Joe Daddy has a lot of great information about Model Railroading Urban Legends which covers more than just DCC. His Legend #5 is one that always gets me – “Use the biggest wire for your DCC bus that you can, preferably 12 gauge twisted.”

First, have you ever tried to twist 12Ga. wire? Second, why would you need heavier wire for your layout than what’s used to carry power throughout your house? Most home wiring uses 14Ga. wire to carry 110 volts at 15amps! Most DCC layout wiring carries 15 – 20 volts at 5amps.

The pundits of heavy wire state that there is less resistance in the larger wire resulting in less power loss. Some hunting on the web shows that 16Ga. copper wire will lose about 6.5v over 100m (328ft.), while 14Ga will lose about 4v in the same distance (at 5 amps). This would be a problem on some very large layouts but not so much for the average home layout. If voltage loss is a concern you should place the command station/booster in the middle of the section it is powering to reduce the wire run as much as possible. If your runs are really long, adding boosters to the middle of power blocks will help.

I used 16Ga stranded wire. Apparently, stranded wire should have less power loss because electricity runs on the surface of the wire. So, more wires equals more surface area equals less power loss.

Steve Jones has several pages dedicated to DCC Myths on his blog – Electric Nose. The one that irks me the most is the issue of DCC Friendly Turnouts (being in the UK Steve calls them “points”). Some websites scare modelers away from DCC by telling them they need to make a tons of modifications to their turnouts before they can run DCC. Steve points out that it is not a problem of DCC, it is more often a problem of wheels, or the turnout, being out of gauge.

I’ve built two DCC layouts of my own, and helped friends with several more. We have never had to do anything more than insulating the frog rails on power routing turnouts to avoid shorts. Well, there were a few used turnouts that we had to set the gauge of the point rails and some that we had to shim the guardrail, but those were more of a derailment issue than a shorting issue.

DCC command stations are much more efficient at detecting shorts than DC systems are. When trains are run on a DC layout there may be shorts happening all over the layout, but neither you nor the DC controller notice them so the trains keep rolling along. DCC systems are very sensitive to shorts since the power output (5 to 10 amps) is generally much higher than DC systems. They shut down at the first sign of a short to protect the layout. So a layout that seemingly runs fine on DC may not run quite so fine on DCC. But that not a problem of DCC, it’s a layout problem and is rarely very difficult to fix.

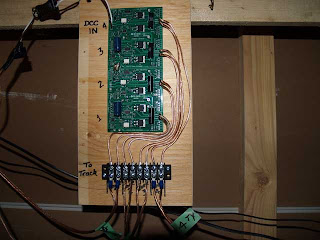

You’ll see a lot of layouts on the web that have what looks like very complicated wiring. Some people will think that’s because they use DCC. On those layouts DCC is only a small part of all the wiring. Items like electric turnout controls, signal systems, occupancy detection, and scenic lighting all add to the wires running under a layout. You shouldn’t just look at a picture of complex wiring and think “DCC”. Read the text and see what else they’ve got going on their layout. Remember, DC layouts can have much more complex wiring than DCC layouts due to multiple throttles and power blocks.

Railroadman, Daryl Dankwardt, has a great post about complex wiring – Don’t be Intimidated by all the Wiring – that shows photos of his wiring. It looks complex, but he uses DC and is doing a lot with all those wires. He has electric switch machines and has a control/dispatcher’s panel with LED indicators, turnout controls, and throttle selection switches. His wiring is very neat, especially when compared to some other layouts I’ve seen.

Scott